Die Cutting Methods

Steel Rule Die Cutting

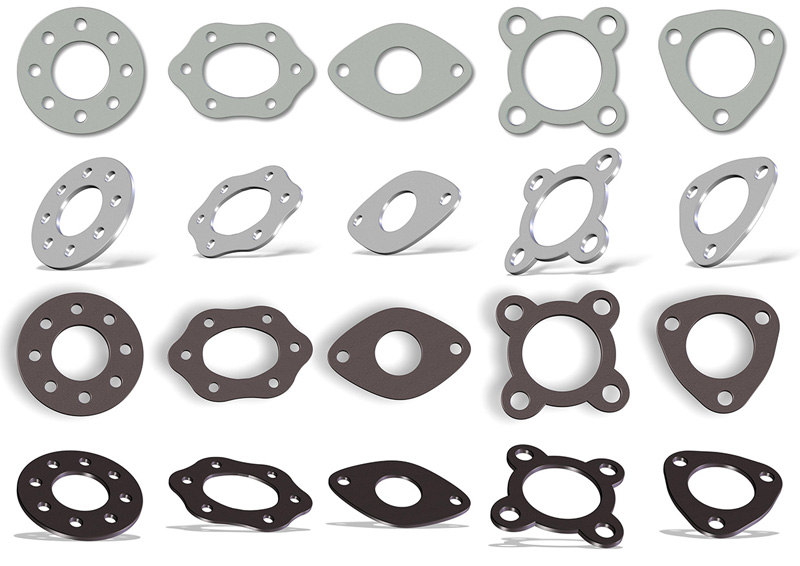

Steel rule dies are inexpensive tools and are used to cut a large percentage of the custom die cut parts that are produced at M&P Sealing. Our steel rule dies can be made from a variety of rule styles and bevel configurations. Custom die-cut parts may be designed to have internal round holes, oval slots, or square and rectangular cutouts. With so many choices in rule and punch styles, it is routine that our design team learn as much as possible about your application and process before designing the optimum die for your part.

While using steel rule dies, we are able to supply parts in individual pieces, individual pieces with a “kiss-cut” tab, individual pieces with an extended liner, and “kiss-cut” on a roll. Since 1998, M&P Sealing has cut almost all known non-metallic materials using steel rule dies including, but not limited to, cork, cork/rubber, foam, felt, sponge (open and closed cell), mechanical rubber, cellulose fibers, vegetable fiber, plastics, paper, and chipboard.

Rotary Die Cutting

Rotary die cutting is the optimum cutting process for applications that specify thin materials (up to 1/8″ thick.), adhesive backed products, and involve large quantities. Our rotary presses allow us to die cut most non-metallic materials with an adhesive on one or both sides in parts as small as 1/16″ dia. up to 9-1/2″ wide x 17″ long or any size and shape in between.

Our rotary die-cut parts can be supplied “kiss-cut” on rolls with the web (scrap) removed. Such parts can be designed so that they can be automatically dispensed and placed on the finished part during your final assembly, which further reduces the overall cost of the final unit. Additionally, our rotary die cutting equipment has the ability to print your logo or identification information in two colors, which can help distinguish your product from that of your competitors.

Alternative Cutting Methods

Like laser cutting, waterjets are another alternative to die cutting. Utilizing water pressurized up to 60,000 psi and forced through nozzles with small orifices, high velocity is achieved and almost any material can be cut precisely. Introducing abrasive elements to the water in the nozzle permits cutting of extremely hard materials such as steel, glass, stone, composites, and more. Again, no tooling is required, but like lasers, overall cutting time is much slower than die cutting.