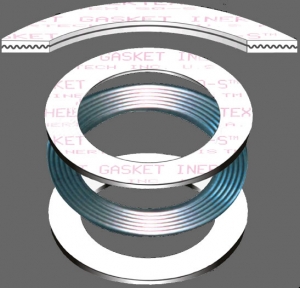

Inertex® Inermet Insertable Gaskets are made with a corrugated metal insert. The typical sheet thickness is 1/16″ (1mm also available,) and the typical metal used is 24 gauge 316L stainless steel. Through the enhanced resilience of the gasket by incorporating the corrugated metal insert, the design is aimed at improving sealing performance for applications involving thermal cycling effects and at low compressive loads.

Product Benefits:

- Enhanced sealing performances at lower compressive stresses

- Enhanced sealing performance and mechanical stability for applications involving thermal cycling

- High blow-out resistance

- Improved rigidity for difficult installation condition

- Standard ANSI/ASME sizes available; custom sizes and styles also available for applications such as heat exchangers

The Inertex® family of gasketing and sealing products are produced by proprietary processes protected by both U.S. and world patents.

All Inertex® products share the following typical properties:

- Pressure range, full vacuum to 3,000 PSI

- Low coefficient of friction (.02 like wet ice)

- Temperature range, -450°F to +600°F

- Extremely soft, excellent conformability

- FDA suitable (FDA 21 CRF 177.1550)

- No aging or hardening in service

- Little creep or cold flow

- 100% expanded virgin PTFE

- pH range from 0 to 14