The Inertex® family of gasket sheets are produced by a proprietary expansion process that generates a highly fibrillated microstructure with nearly equal tensile strength in every direction (ISOTROPIC.) This unique structure maximizes performance predictability and stability, while minimizing creep and cold flow. Whatever your application, Inertex® SQ-S Sheet Gasketing is setting the new standard in providing users with the tightest, most leak-free gasket possible.

Product Benefits:

- Strong and tough, capable of withstanding 40,000 PSI stress without affecting seal ability

- One of the tightest gasket materials in the world; an ultimate solution to the EPA issues

- Unlimited shelf time; no aging, and unaffected by UV, ozone, and corona

- Easily hand cut, die cut, and removable from flange surfaces after use

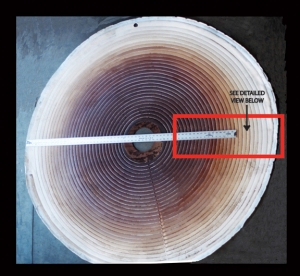

- Largest expanded PTFE sheets in the world (SQ-S “H”); suitable for large diameter flanges without segmenting and improving yield of gasket cutting

- Engineered to replace all filled PTFE sheets in various colors, reducing gasket inventories

- Far exceeding the requirements of SEMASPEC 92010934B-STD for semiconductor uses

- Excellent choice for handling ultra-pure water for biotech and pharmaceutical industries

- Soft and compressible, suitable for FRP, porcelain, plastic, and glass-lined piping vessels

The Inertex® family of gasketing and sealing products are produced by proprietary processes protected by both U.S. and world patents.

All Inertex® products share the following typical properties:

- Pressure range, full vacuum to 3,000 PSI

- Low coefficient of friction (.02 like wet ice)

- Temperature range, -450°F to +600°F

- Extremely soft, excellent conformability

- FDA suitable (FDA 21 CRF 177.1550)

- No aging or hardening in service

- Little creep or cold flow

- 100% expanded virgin PTFE

- pH range from 0 to 14